Being a tree planter is one thing, but starting a tree-planting business is a whole other.

Reforestation is a business just as much as logging is. In fact, the more we log, the more tree-planting businesses we should have.

As a tree planter myself, I’ve been in the industry for some years now and have observed how the backend works.

I also asked knowledgeable players in the game for additional insight.

This way I can share with you the details to help make a tree-planting business plan. Hopefully, it can provide guidance for courageous souls who want to start a business in the industry.

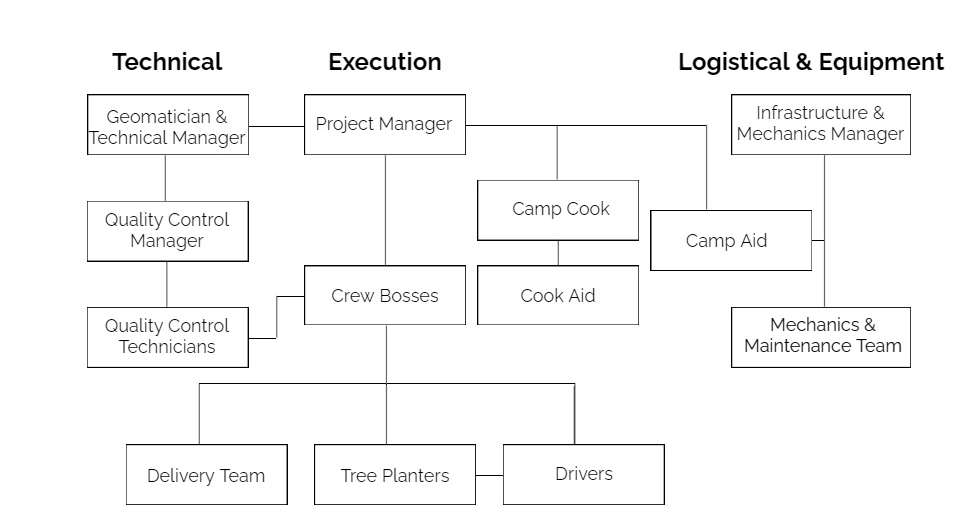

Typical Structure for Tree Planting Operations

This is what a typical structure for the operations sides of the tree planting business looks like:

First, on the technical side, you’ll need a team that manages quality control and map-making.

Second, you need a project manager that executes the strategy with the help of the crew bosses.

Third, don’t forget camp cooks with cook assistants that will feed the camps.

Fourth, you need a team to take care of the logistics of equipment and infrastructure, such as the maintenance of the camps, and the machines.

The Essentials for a Tree Planting Business Plan

If you want to operate a tree-planting business with success, you’ll need some details on the essentials:

Contracts

Every tree-planting business must compete for contracts. There are many factors that affect if your company can be eligible for the contract or not.

But at the base, the price you can offer for a contract will generally be what decides if you can get it or not.

2 Sectors

Private Sector: You can get contracts in the private sector, that’s usually for smaller businesses. It means dealing with individuals on private land. For example, old farmer’s fields turned into tree plantations or land that’s been recently cut and needs to be replanted.

Public Sector: Once your business grows, you can become eligible for contracts in the public sector, which means working for the government. These will be large commercial clear cuts in the boreal forest that need to be replanted. It can also be areas affected by wildfires that haven’t shown signs of regeneration.

For a larger company, maybe 75% of all contracts will come from the public sector and 25% from the private sector.

How Contract Bidding Works

The government institution that manages forestry will post tenders.

Companies that see these tenders and want to get them will have to do a few things:

- When the offers appear, maybe in October, the crew bosses along with the engineer will go see the land themselves. From what they see, they’ll make an estimate of costs for the specific land to be planted. (The estimate takes into consideration the quality of the land, the location of it, and the logistical cost of planting it).

- Every company that wants to get the contract send in their estimate to the client (government) in a sort of bidding war.

- Generally, the tree planting business that can offer the cheapest price will get it. For example one company can do it for $0.30 per tree and the other one $0.32 per tree. The former will win the contract.

A lot of things influence the price of a contract, for example:

- Do you have your own camp in the area or do you have to rent?

- Will the land be planted smoothly or is it so bad that you’ll have to pay your planters extra per tree?

- How much will it cost to deliver trees from the nursery to the land?

- Does this land have a high risk for machines to break down or planters to get injured?

- How will the gas costs be to get to the land, and for the machines to drive through it?

- Price in the cost of having checkers, cooks, mechanics, maintenance, and cleaning crew.

Estimates can be seen like this: This land will cost about $0.30 per tree to plant, and that’s our offer.

Maybe their cost is $0.25 per tree, which leaves them a $0.05 per tree margin of profit.

Camps

Camps are a must, and in some provinces like Quebec, it’s required by law.

Usually, tree planting camps are made out of trailers put together into living quarters.

Each living quarter has bedrooms with bathrooms and showers.

Additionally, there are blocks for administration and a dining room/kitchen.

A camp might also have a mechanic’s shop or a tool trailer for repairs.

There’s a room for the generator, at least some distance from the living quarters.

The kitchen has propane tanks and proper electrical outlets for the fridges and appliances.

Additionally, there’s usually a games room and a laundry room.

Camps need access to water like a well or a lake, and some filtration system.

With this in mind, if you don’t buy one that’s already established, you’ll need to hire a slew of people to build it.

Machinery

There’s a variety of machinery required for a tree-planting business to operate:

- Muskegs: To deliver trees on the land.

- Company trucks & trailers: For the crew bosses, the delivery drivers, the quality control crew, and the engineer.

- Van/Bus: For the planters to drive to and back from the planting spots.

- ATVs or 4x4s: For the crew boss to drive from one spot to another, or drop off planters.

- Generators: To supply power for the camps.

- Water Pumps: To water the trees before they get planted.

- Tool Truck: For the mechanics, when going from camp to camp.

- Communications: Radios in the trucks to enable comms between the crew bosses, planters, and technicians.

The best companies buy or build their own camps. This enables them to continue to plant trees in the same area year after year, and offer better pricing on contracts.

Keep in mind this is how some tree planting companies operate in Quebec, and that it certainly operates differently elsewhere.

But this is coming from what I’ve experienced in the best tree company I’ve had the pleasure to plant with.

Staff

- Tree Planting Crew

- Brush Cutting Crew

- Quality Control Crew

- Delivery Drivers

- Crew Bosses

- Mechanics

- Camp Cooks

- Camp Cleaners

- Geomatician

- Accountant

- Forest Engineer

- Project Managers

- Environment Coordinator

- Health & Safety Coordinator

All of this staff is required to get the clockwork of a tree-planting business spinning.

Let’s get into details a little bit more about each:

Tree Planting Crew

The tree planting crews are out on the field Monday to Friday, and sometimes Sunday morning. Their usual hours are from 6 am to 4 pm.

The earlier they get on the field, the better, as long as you can actually see the land.

Mornings are just the best time because it’s cool, the sun isn’t glaring yet and the bugs are at their lowest.

Tree planters get up, prepare their lunches, eat breakfast and hop into what we call panels (those long white vans).

Every panel (usually 2-3 in total) has a dedicated driver, usually a veteran tree planter.

The panels carry upwards of 10 tree planters each, which hop on with their planting harnesses, tools, backpacks, and water.

There’s a rack on top of the panels to put your gear and tools for transport.

From there, the driver (who’s paid for the time he drives) takes his crew to the patch (where we plant).

When the tree planters arrive, the trees should already be set for them to start. The crew boss points them to their land and gives them a visual with a GPS map.

From this point on, the planters walk to their spots and start planting until the end of the day.

They are paid per tree, and the price per tree depends on the size of the tree and the difficulty of the land.

By 3 pm, they’re ready and waiting by the road to be picked up by the driver.

After that, the planters head back home, shower, eat supper, relax a little, and head to sleep.

Quality Control Crew

The quality control crew gets up at the same time as the planters. They eat breakfast, prepare their lunch and hop into their trucks.

When they arrive at the patch, they consult with the crew boss, then get ready to check lands that already have been planted.

They know who planted where, and when they planted.

Usually, the quality control crew will check trees on the same day or within a day or two after the trees are planted.

What the quality control crew check for:

Tree survival is primordial for tree planting companies, quality control crews need to check correctly because the big client at the end also checks.

Here are their criteria for a quality-planted tree:

- Is the tree planted deep enough? It has to be slightly below soil level.

- Is the tree planted straight? There’s only a small tolerance for a visible angle with the tree, if its too slanted, it won’t grow straight.

- Is the tree planted in the correct soil? Trees do best in mineral rich soil, it’s not acceptable for a tree to be planted directly in moss.

- Is the tree compacted enough? If the checker can pull out your tree by tugging at it, it needs more compaction.

- Is the tree planted damage free? Is the main stem still intact or is it broken? How is the root system, has it been broken?

- Is the hole free of air pockets? Air pockets undergroud will dry roots out and eventually kill the tree.

- Is the planting density correct? 1.6m to 2m in distances per tree. Each tested area needs to have a specific number of trees.

There’s a margin for error but in general, 85% to 100% scores is where it needs to be.

When the tree checker deems the tree planting quality is too low, he informs the crew boss.

The crew boss goes to the planter and mentions the problem, and the tree planter must go back to replant the trees.

The quality control crew spends their day going from land to land testing the quality of the tree planter’s work.

When they end their day, they hop back in their trucks and finish their day just like planters do.

Brush Cutting Crew

The brush cutting crew operates independently from the tree planting crew. They are out clearing weeds on older plantations.

Similar to planters, they also have their own quality control crew to check on their work.

Brush cutters are also paid by production, which is a certain amount of dollars per hectare they clear of weeds.

Despite working independently, tree planting and brush cutting operations are directly tied.

Which means the numbers of brush cutting contracts are directly proportional to the numbers of tree planting contracts.

While tree planting may be the main activity within the business, brush cutting plays an important role.

Brush cutters go to lands planted by the company several years prior. It can be plantations from 5, 10, 15, or more years ago.

The quality control crew passes after to check on their work. They decide if the quality is acceptable, which depends on standards set in place by the employer.

Since some lands are better than others, they are usually given randomly, or chosen by the foremen in a fair and logistical manner.

Brush cutters have their own setup, for example, a truck with an ATV, a brush cutter, and some jerry cans.

They don’t go around cutting everything though, brush cutters have a good knowledge of beneficial plants and weeds.

They do a selective clear, taking away weeds and leaving behind the best plants.

Delivery Drivers

There are two types of delivery drivers:

- The ones that bring trees from the tree nurseries to the site of planting.

- The ones that work on the land, and drop trees in strategical stashes with the crew boss.

The Truckers

The ones who bring the trees over are the truckers, who might drive hundreds or thousands of kilometers to bring the trees over.

Once they arrive on the site, they get ready to unload their vans.

Sometimes they’re required to do it alone, but most of the time, tree planting crews will alternate to help the driver unload his van.

That involves unloading steel racks filled with tree trays. Each tray holds from 25, 36, 45, 67, or 113 trees.

For example, one steel rack can hold 40 trays which hold 45 trees each, for a total of 1800 trees per rack.

A van holds around 55-56 racks, which makes a whopping 100,000 trees per van.

After all the racks are unloaded, the driver uses his lift to re-load the van with the empty racks.

The Muskeg Drivers

The muskeg drivers deliver the trees on the land, in strategic locations for the tree planters to plant.

They get up with the crew boss and ensure trees are delivered on the field beforehand.

This way when tree planters arrive, tree boxes are already placed on their lands in calculated stacks.

During dry periods, they also water the trees that aren’t planted yet to make sure they don’t dry out.

The delivery driver finishes with a second round to pick up the empty tree trays.

The best muskeg drivers have some experience in mechanics and can do some maintenance on their machines.

A driver has two priorities, keep your muskeg in top shape, and keep the trees alive.

Like the crew bosses, muskeg drivers work 6 days a week and are paid by the day.

Their only big day off is Saturday. Then Sunday morning they are back at it preparing the land for the planters on Monday.

The muskeg drivers also work with the crew boss to stack the empty trays onto skids. They then wrap them up for transport back to the tree nurseries.

The Crew Bosses

The crew boss is the brains of the operations. He ensures each patch of land has the right number of trees and is planted smoothly.

Every tree planting business plan needs emphasis on crew boss selection. They need to be good leaders, diplomatic, and stress tolerant.

It’s their job to know every tree planter. When they know their planters’ pace and style, it’s much easier to manage and calculate the patches.

For the highest efficiency, they place planters strategically in lands they know they’ll finish in a certain amount of time.

To be a good crew boss you need a certain set of skills:

- Good time management: You need to complete certain contracts within a time limit to stay on track for the summer’s tree goals.

- Good foresight: You need to be able to visualize the lands, and how the planting will go ahead of time to maximize the strategy.

- A strong spirit: You always need to keep a positive attitude, and encourage tree planters and yourself when times are rough.

- Patience: Some tree planters are harder to deal with, and as the crew boss, it’s in your interest to stay cool and composed at all times.

- Resilience: Sometimes you get allocated very hard contracts that seem near impossible to achieve, and resilience is key to finishing them.

As a crew boss, a lot of responsibility is on your shoulders. There’s a fine balance between micromanaging your tree planters and letting them do their thing happily.

The crew bosses go around during the day to see the progress and distribute planters who’ve finished onto other lands.

They work closely with the muskeg drivers to help unload empty trays & extra trees off the land.

They keep in communication with other crew bosses and the engineer or manager back at the headquarters.

Crew bosses need to make sure every planter is healthy and safe. They might bring you water on extremely hot days or evacuate planters during wildfire alerts.

They’ll deal with problems such as bears bothering some planters or muskegs running into mechanical problems. Or when a planter runs out of trees to plant, the crew boss brings them trees or transfer them elsewhere.

They also keep in communication with the quality control crew. They talk with the tree planters when the quality is poor and enforce the rules when land needs to be replanted.

As a crew boss, you want to achieve from 85% to 100% quality in lands you manage.

They get paid by the day no matter the hours and work 6 days a week.

They’ll always get up before the tree planters and leave the patch after the tree planters.

Being a crew boss is no easy job, it takes a whole lot of guts.

The Mechanics

The mechanics work on the backend, fixing and maintaining machinery. They’re very important because the forest is a harsh mistress on machines. Maintenance and repairs made right there at the company save a lot of time and money.

They might help planters with their equipment but mostly will be working on fixing company trucks, muskegs, generators, etc.

The mechanics might not always be at the same camps that the planters are, they’ll go from camp to camp for their job.

The Camp Cooks

Camp cooks are pillars of the business, good food makes happy workers, and happy workers mean a productive crew.

Their working hours are straining, cooks wake up even earlier than the planters to prepare breakfast. In the evening, they rush to prepare supper.

A camp can have upwards of 50 workers, that’s a lot of mouths to feed and a lot of food to cook.

They need to calculate the amount of food required for each order and ensure it arrives on time.

Camp cooks, due to covid prepare all lunches for tree planters, including what they eat on the patch. They’ll also set up food bars for people to customize their lunches.

Cooks make plants for a good rotation of healthy foods packed with nutrition. They also take into consideration vegetarian options.

You can see that their job is stressful and definitely not easy.

Camp Assistants

Camp assistants can’t be overlooked, tree planters are a dirty bunch, and dirt piles up quickly if nobody cleans it.

Most camps have dry rooms planters use to quickly dry their boots and gear, there are shared bathrooms and garbage cans all over the camp.

It’s important to have someone dedicated to cleaning because bears might come around more often if things are sitting around too long.

Clean quarters do a great part in keeping workers feeling great, they’ll notice it and be thankful for it.

Camp assistants will also help with any small labor jobs around the camp.

The Geomatician

The geomatician’s job is to interpret the GPS data and provide maps to the crew bosses, the tree planters (If needed), and the brush-cutting crew.

The maps represent the designated patch to re-plant or to clear the competition.

Maps aren’t just provided by the government, the company has to create them in order to maximize its production.

They help the crew boss plan his operations and the tree planters know exactly where they need to plant.

Not all blocks are even and square, many places to replant are long strips or terrain with weird shapes. Without a map, sometimes it can get really confusing to know where you need to plant.

The Accountant

Every good company needs an accountant, of course, tree planting is no different.

It can get complicated to compile all the scores for each tree planter, adjust the price per tree, and deduct the percentage of trees per cassette given by the tree farms.

A good accountant makes everything smoother, helps you deliver your tree-planting and brush-cutting crew with accurate paychecks, and overall keeps everyone happy.

The Project Managers

The project managers execute the strategy for the tree planting side and brush cutting side. They will be hiring staff, hand-picking the crew bosses, betting on contracts, and communicating with the clients.

The Forest Engineer

The forest engineer is the architect behind logging, tree planting, and brush cutting. The best tree-planting companies have a forest engineer in the back end.

Environmental Law Coordinator

You need to uphold environmental law, as your company will be followed and checked. An environmental law coordinator will communicate with the government and ensure the company respects the law.

Health & Safety Coordinator

Tree planting businesses are labor-heavy companies, which means you will need a health and safety staff to manage the injuries and teach preventative measures to your workers.

There are also laws here to follow, a good health and safety manager will make sure these are followed and respected.

Conclusion

To recap the essentials of a tree planting business, you need the following aspects to run efficiently:

- Staff: Tree planters, quality checkers, brush cutters, crew bosses, delivery drivers, camp cooks, mechanics, camp assistants, geomaticians, an accountant, project managers, environmental & health coordinators, and a forest engineer.

- Contracts: You need to bid and win against other companies for contracts.

- Machinery: Trucks, muskegs, ATVs, generators, pumps, communications, etc.

- Camps: Camps for the staff to live, sleep and shower at.

When you understand all these aspects, you have a good base for a tree planting business plan.

Welcome to the forestry industry!